Improving Sample Accuracy and Product Quality

Accurate and reliable sampling is an important safety requirement in food manufacture. It helps ensure quality from batch to batch, supports compliance with government regulations and industry rules, and builds trust with your customers.

Sustainable Sampling

TrueSampler™ is the solution to that challenge.

Product sampling can also be a major source of waste and inefficiency. With industry-leading accuracy, near-continuous automated sampling capabilities, and immense flexibility in scale and size, it’s a sampling system for demanding manufacturers intent on building trust with their customer base.

A Look Inside The TrueSampler™ Process

-

The TrueSampler™ can be adapted and set up for almost any manufacturing process. Not only will it cut down on labor costs involved with sampling, but it will also eliminate the waste of product and packaging materials associated with “grab sampling”. In fact the savings on this aspect alone can yield and ROI of under 9 months on the cost of the equipment. Here, you see one way it integrates into a pet food manufacturing line.

-

With precision, as the product descends from the hopper into the weighing and bagging system, the sample collection valve opens, and a predetermined amount of product is precisely pulled via air suction into the collection tube.

-

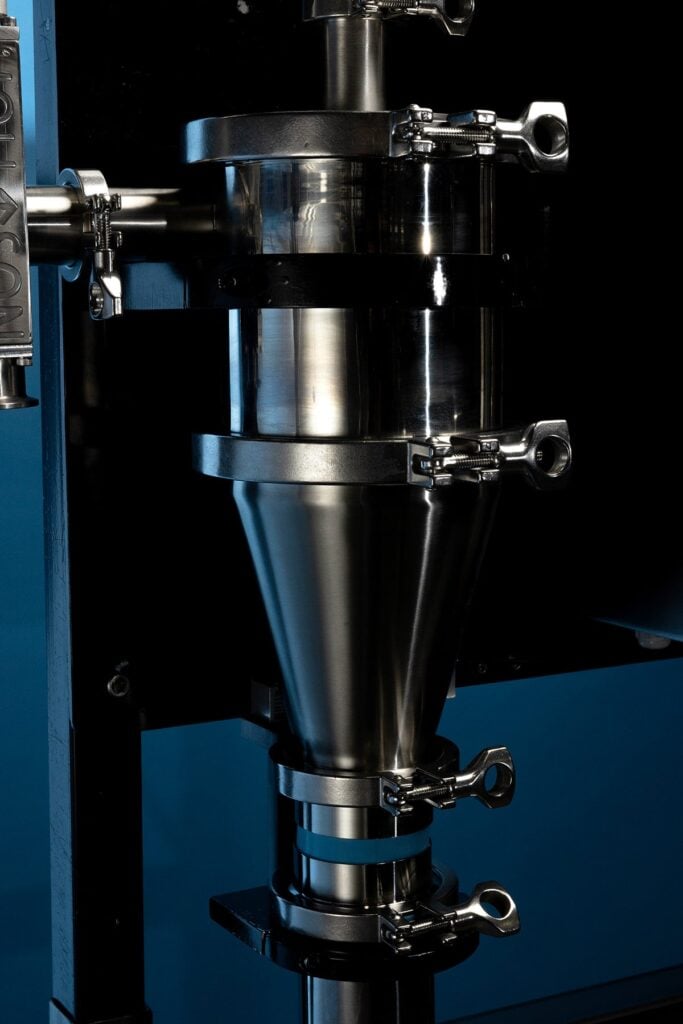

The product enters the cyclone after traveling through a sanitary flex hose or rigid pipe. When it enters the cyclone, the air exits through the top, and the product particles make their way to the bottom and fall down the sample tube. A scale measures how much product is collected and determines if there needs to be any adjustment to how long the sample valve needs to stay open for the next sample taken. This process significantly reduces waste and increases overall efficiency.

-

The product samples descend the tube and are deposited sanitarily into a collection bag, removing the risk of human contact and cross-contamination.

Contact Us Today to Learn More About the TrueSampler™ System and How It Can Fit Your Needs.

TrueSampler™: Quality, Safety, and Savings

Product sampling introduces many challenges. One of the most critical is that the predominant sampling method, grab sampling, introduces blind spots. The TrueSampler™ is capable of near-continuous automated sampling frequency, which delivers a statistically superior sample for testing.

TrueSampler™ also delivers additional benefits for manufacturers, including:

Reduced opportunities for cross-contamination thanks to the sanitary sampling method. The TrueSampler™ system eliminates the need for human contact, increasing food safety.

More accurate and thorough sampling leads to better decision-making for food safety and quality. Manufacturers can rely on the TrueSampler™ to make informed decisions.

Eliminated waste in the form of product and packaging materials traditionally lost in grab sampling. Simply eliminating this waste can yield an ROI that pays for itself in under nine months. Let the TrueSampler™ system improve your quality program and your bottom line.

Customized size and capacity. Every manufacturer has unique constraints in the form of space requirements, testing volume, and more. The TrueSampler™ system can be customized to meet any combination of needs, resulting in a flexible, scalable solution that helps support product safety and peace of mind.

Your business deserves a sampling system that fits its needs.

Contact us for more information about the TrueSampler™ system and its benefits.